Facilities

BUMI are to provide differentiated quality mass production to complete the available equipment and facilities.

PRESS production facilities

| Equipment |

Spec./Capacity |

Q’ty |

Equipment |

Spec./Capacity |

Q’ty |

| NC Feeder |

YNLF 30S |

1unit |

NC Feeder |

YNLF 50S |

1unit |

| NC Feeder |

YNLF 35E |

1unit |

NC Feeder |

YNLF50H |

2unit |

| NC Feeder |

YNLF 40S |

1unit |

NC Feeder |

YNLF60M |

3unit |

| NC Feeder |

YNLF 50M |

1unit |

- |

- |

- |

| Knuckle Press |

100 T0N |

1unit |

Knuckle Press |

110 TON |

2unit |

| Knuckle Press |

150 TON |

1unit |

Knuckle Press |

200 TON |

2unit |

| Knuckle Press |

250 TON |

1unit |

Knuckle Press |

300 TON |

1unit |

| Knuckle Press |

400 TON |

1unit |

- |

- |

- |

| Mechanical Press |

200 T0N |

2unit |

Mechanical Press |

160 TON |

3unit |

| Mechanical Press |

150 TON |

1unit |

Mechanical Press |

110 TON |

2unit |

| Mechanical Press |

80 TON |

5unit |

Mechanical Press |

60 T0N |

2unit |

| Mechanical Press |

35 TON |

2unit |

- |

- |

- |

| SPOT Welder |

100KVA |

4units |

SPOT Welder |

75KVA |

1unit |

| SPOT Welder |

30KVA |

1units |

- |

- |

- |

Development Facilities(R&D-Line)

| Equipment |

Spec./Capacity |

Q’ty |

Equipment |

Spec./Capacity |

Q’ty |

| Radial Drillng M/C |

- |

2unit |

Contour M/C |

- |

1unit |

| Milling M/C |

- |

2unit |

Bench Drill M/C |

- |

2units |

| Lathe for General Use |

- |

1unit |

Surface Grinding Machine |

- |

1unit |

| Contour Grinding M/C |

- |

2units |

- |

- |

- |

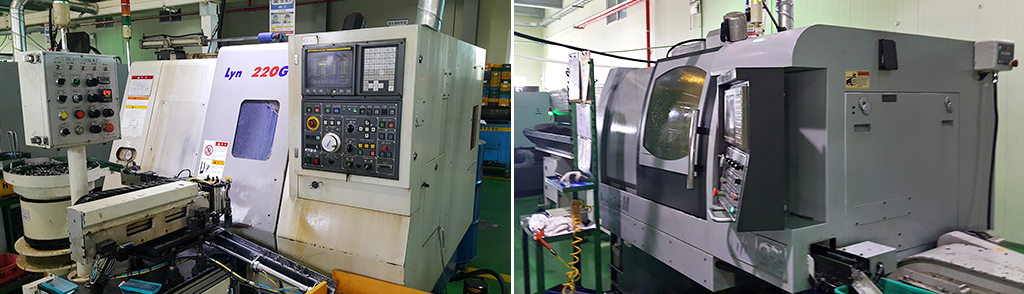

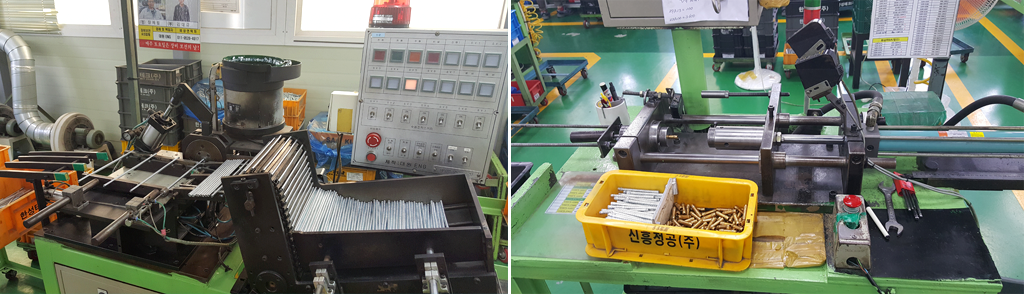

Metal Production Facilities

| Equipment |

Spec./Capacity |

Q’ty |

Equipment |

Spec./Capacity |

Q’ty |

| CNC Lathe |

- |

18units |

Eey Joint Automatic Marking M/C |

- |

1unit |

| Automatic CNC |

- |

6units |

Lathe for General Use |

- |

1unit |

| BH Automatic Marking M/C |

- |

1unit |

Manual Marking M/C- 1 |

- |

1unit |

| 2dies Form Rolling M/C |

- |

1unit |

Manual Assembling M/C |

- |

1unit |

| BOLT Swaging M/C |

- |

2units |

Ultrasonic Cleaners |

- |

1unit |

| EYE JOINT Automatic Deburring M/C |

- |

2units |

EYE JOINT Burnishing M/C |

- |

1unit |

| CONNECTOR Semi-automatic Ass'y M/C |

- |

1units |

NIPPLE Automatic Ass'y M/C |

- |

1unit |

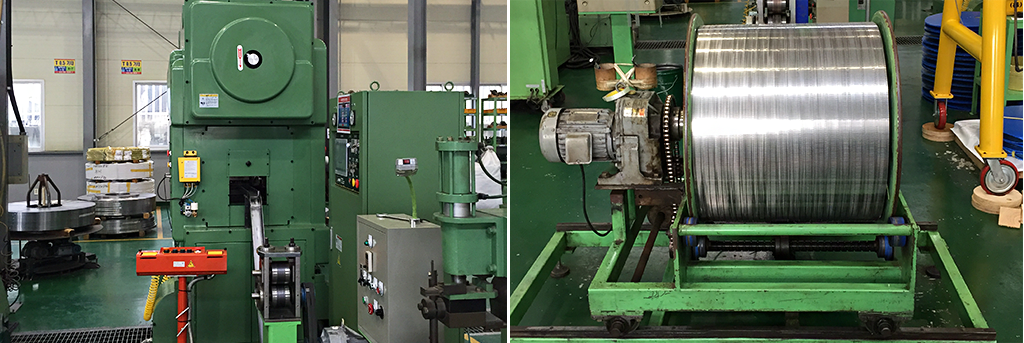

Spiral Facilities

| Equipment |

Spec./Capacity |

Q’ty |

Equipment |

Spec./Capacity |

Q’ty |

| SR Manual Assembling M/C No.1 |

Swaging M/C |

7units |

Winding M/C |

Winder |

1unit |

| SRB Manual Assembling M/C |

Swaging M/C |

1unit |

Spiral Air Washer |

Air Washer |

1unit |

| Orifice Manual Assembling M/C |

Orifice Assembling M/C |

1unit |

Spiral Inner Diameter Beveler |

Inner Diameter Beveler |

2units |

| Orifice Automatic Assembling M/C |

Orifice Assembling M/C |

1unit |

Spiral Outer Diameter Beveler |

Outer Diameter Beveler |

1unit |

| Steel Wire Rolling M/C |

Wire Rolling M/C |

1unit |

Spiral Cutter No.1 |

Cutter |

5units |

| Iron Wire Rolling M/C |

Wire Rolling M/C |

1unit |

Spiral Cutter |

Cutter Grinding Stone |

2units |

| Automatic cap(Swaging M/C) No.1 |

Swaging M/C |

6units |

- |

- |

- |

Metal Facilities

| Equipment |

Spec./Capacity |

Q’ty |

Equipment |

Spec./Capacity |

Q’ty |

| SPOT Welder |

35KV |

12units |

High-Speed Presser |

45 T0N |

9units |

| Rolling Cutting Machine |

Rolled M/C |

4units |

- |

- |

- |